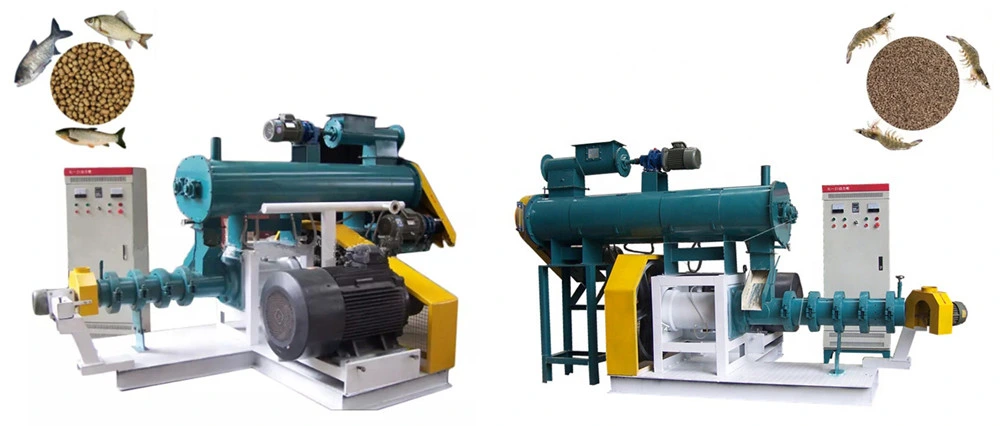

Large Capacity Screw Fish Feed Extruder Processing Line Shrimp Feed Machine Plant

Description

Basic Info

| Model NO. | DSP-135B |

| Customized | Customized |

| Model | DSP-135b |

| Output | 1000kg Per Hour |

| Main Power | 75kw |

| Feeding Power | 1.5kw |

| Cutting Power | 2.2kw |

| Conditioner Power | 3.0kw |

| Voltage | 380V, 50Hz, Three Phases |

| Screw Diameter | 135mm |

| Material of Conditioner | Stainless Steel or Carbon Steel |

| Dimension | 3750*1980*1800mm |

| Weight | 2500kgs |

| Export Package | Film Packing, Wooden Case |

| Fish Feed Size | 1mm to 15mm |

| Keyword 1 | Floating Fish Feed Machine |

| Keyword 2 | Shrimp Feed Making Machine |

| Transport Package | Wooden Case |

| Specification | 3750*1980*1800mm |

| Trademark | AG Mach |

| Origin | Henan, China |

| HS Code | 8438800000 |

Product Description

China Factory Wet Type Fish/Pet Food Pellet Extruder Floating Fish Feed Machine

Product Description

Fish feed production line can be widely used in the production feed of fish , shrimp, crabs, abalone, sea cucumbers and various ornamental fish .It is an ideal choice for manufacturers with rigid requirements. The production line has some advantages: small investment, high output, small floor area.The production line adopts internationally advanced twin-screw extrusion technology. The fish feed production line is suitable for fish food at different growth stages.The fish feed shapes and sizes could be various by changing the mould.In addition,it also could produce dog food, cat food, fox food, rabbit food,shrimp food and so on.1. The floating fish feed extruder machine is widely used for producing variety materials into high-grade aquatic feed pellets for fish, catfish, shrimps, crab etc.2. The final products have unique shape and good taste, high nutrition and smooth textures.3. For feeds of fish and shrimp, the floating time in water can be adjusted by the extrusion degree adjustment.4. The wet type floating fish feed machine is an ideal for small and medium fish farm holders or feed processing plant.5. Feed pellets dia. Is 0.9-15mm.

Product Parameters

| Model | Capacity (T/H) | Main Power (kw) | Feeding Power (kw) | Cutting Power(kw) | Conditioner Power(kw) | Sscrew Diameter (mm) | Dimension (mm) | Weight (kg) |

| DSP-60B | 0.18-0.2 | 15 | 0.4 | 0.4 | 0.75 | 60 | 1780*1250*1300 | 480 |

| DSP-70B | 0.25-0.3 | 18.5 | 0.6 | 0.6 | 1.1 | 70 | 2460*1550*1740 | 940 |

| DSP-80B | 0.35-0.4 | 22 | 1.1 | 0.75 | 1.5 | 80 | 2650*1450*1750 | 1000 |

| DSP-90B | 0.5-0.6 | 37 | 1.1 | 1.1 | 2.2 | 90 | 2600*2100*1900 | 2000 |

| DSP-120B | 0.7-0.8 | 55 | 1.1 | 1.5 | 2.2 | 120 | 3200*1950*1900 | 2200 |

| DSP-135B | 1-1.2 | 75 | 1.5 | 2.2 | 3.0 | 135 | 3750*1980*1800 | 2500 |

| DSP-160B | 1.8-2 | 90 | 2.2 | 2.2 | 4.0 | 160 | 6600*2800*2330 | 3800 |

| DSP-200B | 3-4 | 132 | 2.2 | 3.0 | 5.5 | 200 | 6600*2900*2350 | 4500 |

Raw materials for fish feed

1) Rice Husk: contain 10-14% of protein and also contain vitamin B1, B2, B6 and small quantity of enzyme.2) Mustard Cake: Mix max 40% of cake in the fish feed. Mustard cake contain 30-32% protein. It also contain a high rate of fat.3) Wheat Chaff: contain fiber, control many types of fish diseases.4) Maize: contain protein, carbohydrate, fat, vitamin A and E.5) Cotton Seeds: contain about 54% protein. It is a better ingredients for supplementary fish feed.6) Fish Powder: easily digestible to fish. Fishmeal contain about 55-60% protein.7) Bone Powder: very necessary for building fish-bone.8) Animal Innards: very suitable and ideal feed for catfish. It contain 52% protein.

Product Features

1). Our fish feed processing extruder machine line adopt international advanced technology, the pellets size are very even.2). Pellet diameter is 0.9mm-15mm by changing the mold. We can adjust the cutter speed and the dies to get the different diameter and the length product; 3). The fish feed pellets can float on water for over 20 hours. And sinking and floating aqua-feed pellets both can be made just by adjusting the feed formulation.4). The feeding speed,cutting speed,temperature all can be adjusted.5). The Electric heating device system can control the temperature accurately6). High temperature and high pressure can kill the salmonellosis andbacterial infections. 7). The fish feed extruder machine also can make feed for pet like dog,cat with different shapes and we can customized the shape for you.

Working Principle

There is no need to heat outside the machine, through the screw extruding of the raw material, heat is produced and gathered during the rotary working process in the airtight environment, and during the high temperature ripening process, the starch and fiber of the raw material become swell. Then under the pressure-tight condition, material will be formed into pellets by shaping mould. At the end, through the high pressure produced by the regular rotating of the screw, after being cut by the forepart cutter which rotates regularly and high-speedily, the finished products will be shrunk and become small average puffed balls in room temperature and pressure.

Spare Parts

1) There are one complete set of spare parts assembled on the fish feed machine (screw, sleeve, mould, cutter, heating plate ....)Customer can purchase extra one set of spare parts for replacement or future back-up use.2) The spare parts are made of high quality wear-resisting alloy steel, which are processed by special heat treatment, high hardness, long service life.

Final Products

1) The final feed pellets can float on the water at least for 12 hours. no water pullation. 2) The diameter of feed pellet can be 0.9-8mm, the length of pellets is adjustable.3) The final pellet are with smooth surface and high nutrition.

Floating / Sinking Fish Feed:

Packaging & Shipping

Our Contact