New Brand WPC (wood-plastic composite) Pulverizer

Description

Basic Info

| Model NO. | HWM-1000 |

| After-sales Service | Available |

| Type | Grinding Equipment |

| Processing Object | Beans |

| Processing Technics | Crushing-before-Mixing |

| Screen Mesh | Without Screen Mesh |

| Grinding Equipment Type | Feed Hammer Mill |

| Pellet Mill Type | Ring Die Pelleter |

| Bulking Machine Type | Twin Screw Bulking Machine |

| Expanding Method | Dry Expansion |

| Condition | New |

| Applicable Materials Shape | Powder |

| Main Material | Carbon Steel or 304 Stainless Steel |

| Certificate | CE |

| Spare Parts | Available |

| OEM&ODM | Available |

| Knife Material | Imported From Euro |

| Transport Package | Wooden Pallet |

| Specification | ISO9001 |

| Trademark | LEAP |

| Origin | China |

| HS Code | 8479820090 |

| Production Capacity | 100 Set/Month |

Product Description

New Brand WPC (wood-plastic composite) PulverizerOur Main Products

FeatureHWM turbo mill is a suitable inorganic, organic common ultrafine grinding mill, widely used in low to medium hardness ultrafine material chemicals, dyes, plastics, non-metallic minerals, pharmaceuticals, feed, food and other industries crushing, Almost all heat-sensitive materials for polyvinyl alcohol, PVC, PE, and other fibrous materials can be ultra-fine grinding, the smallest product size up to 2 ~ 5um.

Technical Parameter

MODEL/SPECS | HWM250 | HWM500 | HWM750 | HWM1000 | HWM1250 | |

Productivity ratio | 0.5 | 1 | 1.5 | 2 | 2.5 | |

Grindingchamber diameter | mm | 250 | 500 | 750 | 1000 | 1250 |

Fineness | um | 5~200 | ||||

Max power | kw | 18.5 | 45 | 75 | 110 | 132 |

Air volume | m3/min | 20 | 35 | 55 | 75 | 85 |

Net Weight | kg | 500 | 1100 | 2300 | 3000 | 3600 |

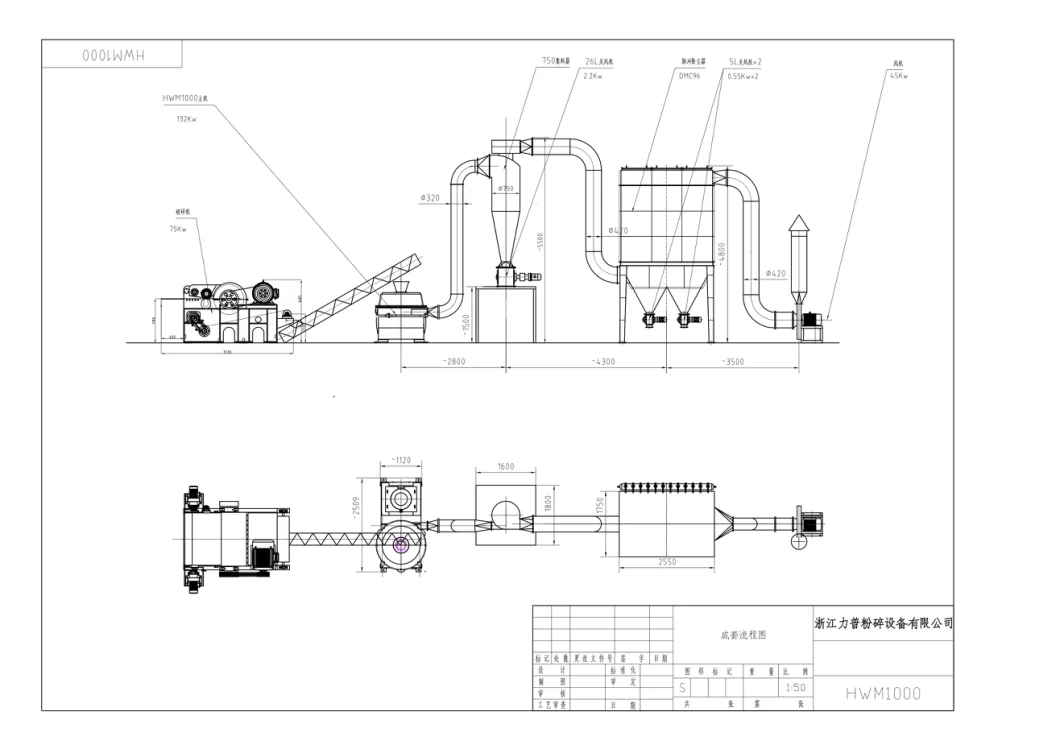

FLOW CHART FOR WPC,SPC

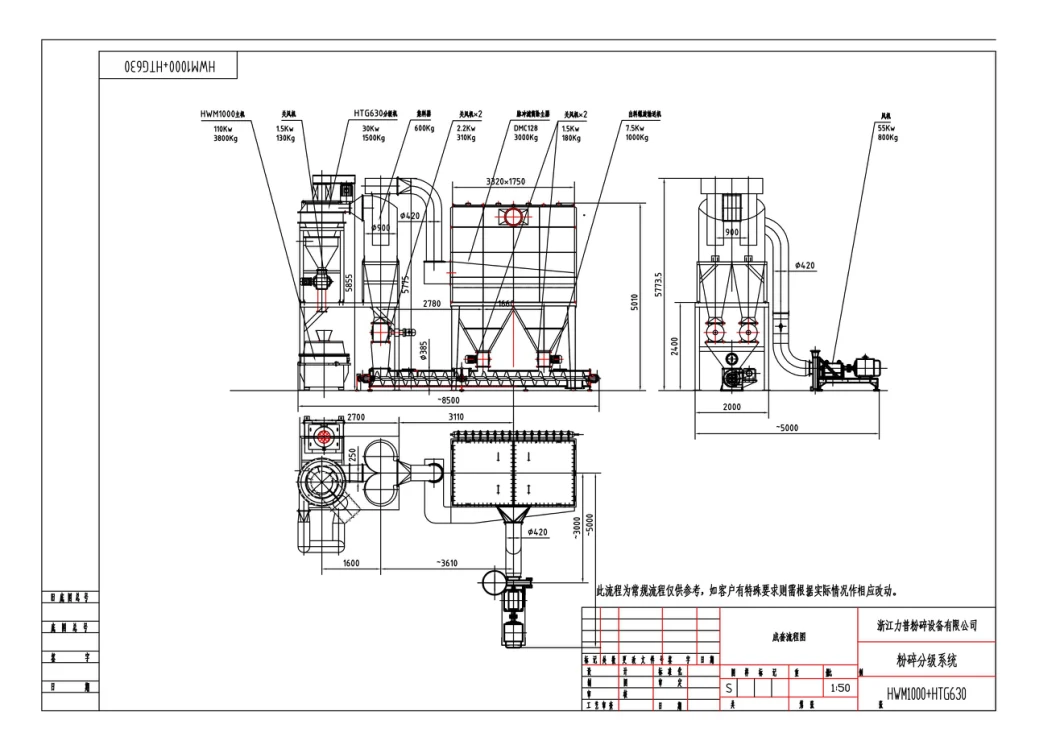

FLOW CHART FOR Nano-Calcium

Related Engineering Cases

Technical support

Upon receiving the deposit, we will offer the following technical services: 1. Design for your production line flow and equipment layout, free of charge; 2. Provide foundation drawings of customer-ordered grinding mills and drawings of related parts, etc; 3. Technical parameters of peripheral equipment will be supplied; 4. Free technical suggestions on adjusting of equipment layout and application. 5. Equipment upgrading (customers need to pay the cost);

Quality assurance 1. Strictly conforming to ISO9001-2000 quality management system; 2. Strict control from purchasing inspection, process inspection to final proofing; 3. Established several QC departments to execute quality control regulations; 4. Detailed quality control examples: (1) Complete files for quality control and quality feedback; (2) Strict inspection for the components of our grinding mills, to assure products free of damage and avoid rust-eaten and paint peeling off later on. (3) Only qualified components will be assembled and total equipment must be inspected completely before sale.After sale service 1. We will send our technician to the site for guiding equipment installation and commissioning. 2. During the installation and commissioning, we offer operator training service. 3. The quality assurance date is one year after commissioning. And after that, we will collect the cost if provide repairing for your equipment. 4. Maintenance for equipment failure caused by improper handling (appropriate cost will be collected). 5. We offer the components with favorable price and perdurable maintenance. 6. If equipment repairing is needed after quality assurance date is expired, we will collect maintenance cost.

Prev: 55kw - 220kw 2-8 Ton/H Heavy Strong Hammer Mill Wood Pulverizer

Next: Woodworking Multi-Functional Wood Pulverizer Hot Search

Our Contact